How is heating provided in Switzerland today?

In Switzerland, more than 78% of the heating in buildings today is provided by boilers fuelled by oil, gas or wood. The remaining 22% is provided by electric radiators, electrically driven heat pumps, and district heating networks (remote heating).

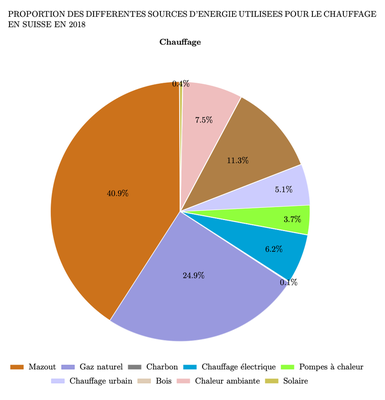

About 67% of the Swiss depend on imported oil for heating: oil (39%) and natural gas (28%) [→ see figure below]. In general, this dependence is tending to decrease: the share of fuel oil has decreased from 61% in 2000 to 51% in 2010 and 39% in 2018, and that of natural gas has increased from 19% in 2000 to 24% in 2010 and 28% in 2018. The share of renewable energy for heating is about 32%. This mainly includes the renewable portion of electricity consumed by electric resistance heaters and heat pumps (8%), biomass (12%), and heat from the environment recovered by heat pumps and solar (7%). In recent years, heat pumps and wood chip furnaces have been gaining ground for individual heating, mainly at the expense of oil-fired boilers [→ Q25].

Individual heating and central heating systems for buildings make up almost all (94%) of the systems used in Switzerland. Remote heating networks provide just under 6% of our needs, but are growing rapidly. They consist of a central heating plant with two pipes (return flow) to distribute heat via a fluid (water, steam) to an entire district. This configuration theoretically allows better control of operations and pollutant emissions than individual boilers, but requires a sufficiently large and geographically close heating demand to be economically viable [→ Q45].

In Switzerland, various sources of heat are used to supply our district heating networks: gas or wood-fired boilers, medium-deep geothermal drilling, household waste incinerators (with or without electricity cogeneration), thermal waste, nuclear power plants, and so on. Remote heating networks can also be powered by heat pumps that use part of the energy naturally present in the environment, for example in lake water, or by recovering waste heat, for example from water treatment plants.

Boiler flue gases contain water vapour formed during combustion. If this water vapour is cooled, it condenses (becomes liquid again) by releasing an amount of heat that can be recovered for heating, rather than being lost with the fumes. This is the principle of modern “condensing” boilers, which have an energy efficiency improvement of 3 to 8% over conventional boilers, and which are becoming more and more widespread. The best efficiencies are obtained by floor heating systems, as they operate at lower distribution temperatures, which favours the condensation process.

In general, the prevailing trend is to reduce heating needs by improving building insulation and making better use of solar radiation entering through windows. Between 1970 and 2014, the heating requirements of new buildings were reduced by a factor of 5, from 210 kWh to approximately 42 kWh of final energy per square metre of heated floor. A very well-designed building needs virtually no heating [→ Q29].

References

- Jochem, Rudolf von Rohr & others (2004)

- Jochem, E., Rudolf von Rohr, P. & others (2004). Steps towards a sustainable development: A white book for R&D of energy-efficient technologies. Novatlantis.

- Kemmler, Spillmann & Koziel (2018)

- Kemmler, A., Spillmann, T. & Koziel, S. (2018). Ex-post-analyse des schweizerischen energieverbrauchs 2000-2017 nach bestimmungsfaktoren. Office fédéral de l'énergie (OFEN).